Robots among your racks

When the talk gets round to automation in logistics, the majority of managers mostly envisage automatic forklifts or stackers for pallets, boxes or goods, which represent investments of tens of millions of crowns. But using these automated devices has its limitations; in reality the operational speed is twice as low while the purchase price can be almost double. This means the return on investment can shift to five years or more.

Our vision differs to this. By deploying modern logistics robots, we know how to automate warehouse processes and thus increase efficiency by 200-300%, with an economic return of one to two years. Now those are completely different figures!

Download the myFABER product list

SOFTWARE

– we connect to your ERP and WMS

– the process involves management and looks at robot tasking, capacity planning and map management for the entire warehouse

SERVICES

– feasibility studies

– designing

– delivering a comprehensive solution

– integrating your internal systems

– favourable financing

– service

ROBOTS

– robots from our own development workshop as well as from international brands

– we automate all of the warehouse processes – transporting pallets, crates and goods

ACCESSORIES

– myFABER comes with all the necessary accessories

– together with robots, these include shelves, racks, conveyors and other components

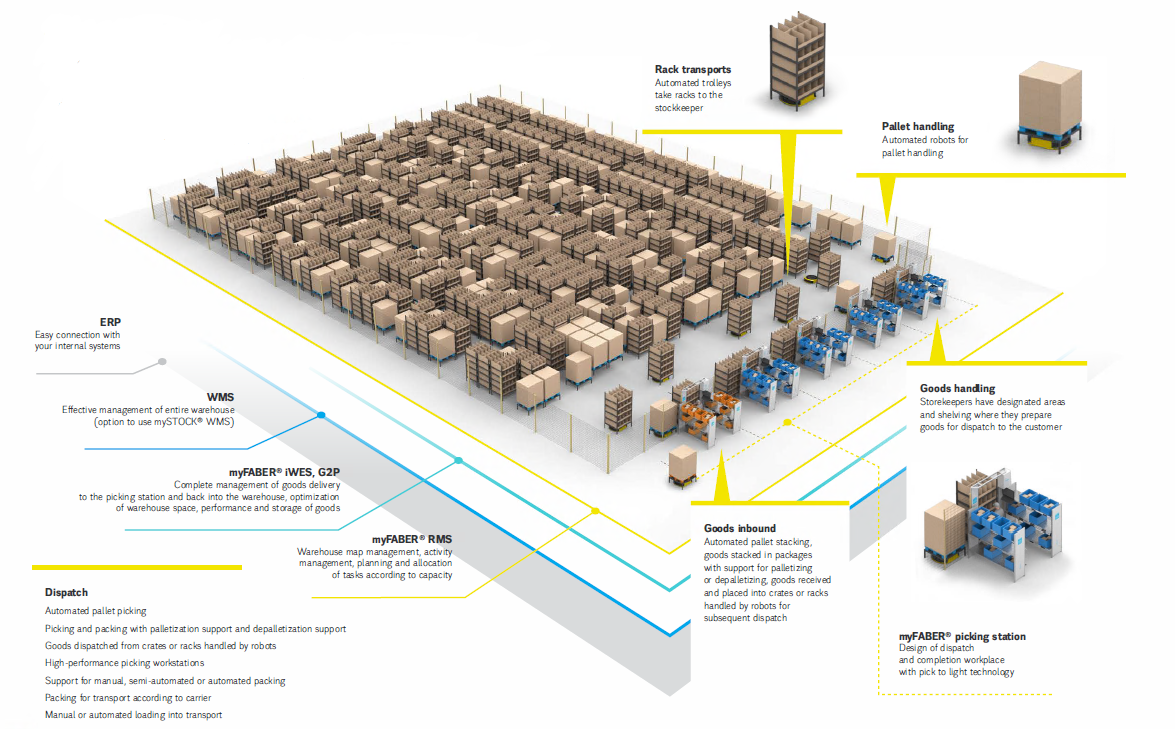

How myFABER® works

Do you want to start using all the benefits of robotics in your warehouse? We connect directly to your ERP or WMS, which we complement with automation processes and the options for using the robots.

We simply integrate the robots into whatever solution you are currently using.

By fully automating and robotizing your warehouse, we cover all areas of warehouse operations.

SOFTWARE

It is necessary to have a WMS in place so the robotic technology can be connected to your warehouse, it doesn’t matter how robust the tool you use is. We have come up with a unique solution on the myFABER® platform, one that can connect to any system. If you are already using ERP software for your warehouse operations and do not use a WMS in your warehouse, or if you are thinking about changing the system, we can make a fresh start together by deploying our mySTOCK® WMS. However, if you already have your own WMS in place, we will supplement it with a section that allows robots to be integrated and connected.

The uniqueness of our myFABER® platform lies in its ability to manage multiple types of robotic solutions from independent and non-integrated manufacturers, each with their own APIs and way of integrating into parent systems. The myFABER® platform integrates them and we simply need to make a single connection to the parent system – be it ERP or WMS. All you have to do is gradually implement the robotic solutions according to your needs and preferences.

Our extensive experience means this is a far easier way for us than integrating individual solutions separately.

SERVICES

We carefully analyse everything

We will make sure that your warehouse automation runs flawlessly and in the shortest possible time. We start by conducting a feasibility study with you and evaluating the return on investment. We will then prepare a logistics study for a comprehensive solution or an audit of the current situation with a proposal for changes.

We supply a comprehensive solution

We will draw up an automation and robotics project so that we can deliver a comprehensive solution that is tailored to your warehouse. We will deliver the individual parts of the solution according to your needs and the extent of the order – WMS (mySTOCK®), iWES, G2P, RMS. You can rely on a fast and efficient implementation thanks to ready-made solutions.

We will connect to your current systems

Connecting to your internal systems so they are fully compatible with myFABER solutions, e.g. ERP, WMS, B2B or B2C e-shop portals, is a matter of course.

Service comes naturally

Our customer care service offers you warranty and post-warranty service up to 24/7/365.

Advantageous financing and subsidies

We offer options for advantageous financing, renting or an SaaS and RaaS model. We will provide help with making applications for subsidies to acquire modern technologies

ROBOTS

We take part in manufacturing and developing a wide range of AGV robots. At our test centre, we assess various types of AGV robots and their use in plants.

The majority of warehouse automation efforts are currently focused on picking and preparing goods for shipment. Now those tens of thousands of steps across the warehouse are a thing of the past. The stockkeeper, or picker, has a permanent workstation and the racks of goods go there, not entirely on their own, but with the help of automated guided vehicles (AGV). This trend is called goods to person (G2P), and brings with it considerable benefits. As already mentioned, the stockkeeper doesn’t have to run around the warehouse, but stays in a defined zone. In terms of safety, this means that the risks of injury are eliminated, while the goods are also protected against possible theft. Finally, let’s face it, even the most conscientious warehouse worker will make the occasional mistake. A robot, on the other hand, works reliably all the time.

The stockkeeper takes care of the next steps necessary for dispatching the goods from the picking station. This leaves them free to do the work for which they are better suited than a robot. They pick the necessary goods from the rack and prepare them for the crate.

We will increase the size of your warehouse

Warehouse robotics allows you to use the full height of the warehouse, which would not be possible with a manually run warehouse. Often this is the only way to make the warehouse bigger, so this factor plays a big part in the decision.

Another important benefit is the storage area can become denser. A densification of 50 percent extra is standard. The robots’ ability to handle heights of up to 8 metres or the use of mezzanine solutions means storage height can be used more efficiently.

Using automatic pallet systems and special shuttle trolley solutions means the aisle can be as narrow as just over a metre wide.

When using a combination of warehousing and stacking storage, then we are looking at warehouse densification of around 50 percent or more.

ACCESSORIES

Thanks to the fact that we are also broadly focussed in the areas of engineering and electrification, we can deliver a complete turnkey solution. This offers a range of accessories to support robotics, racks and other warehouse equipment and its installation.